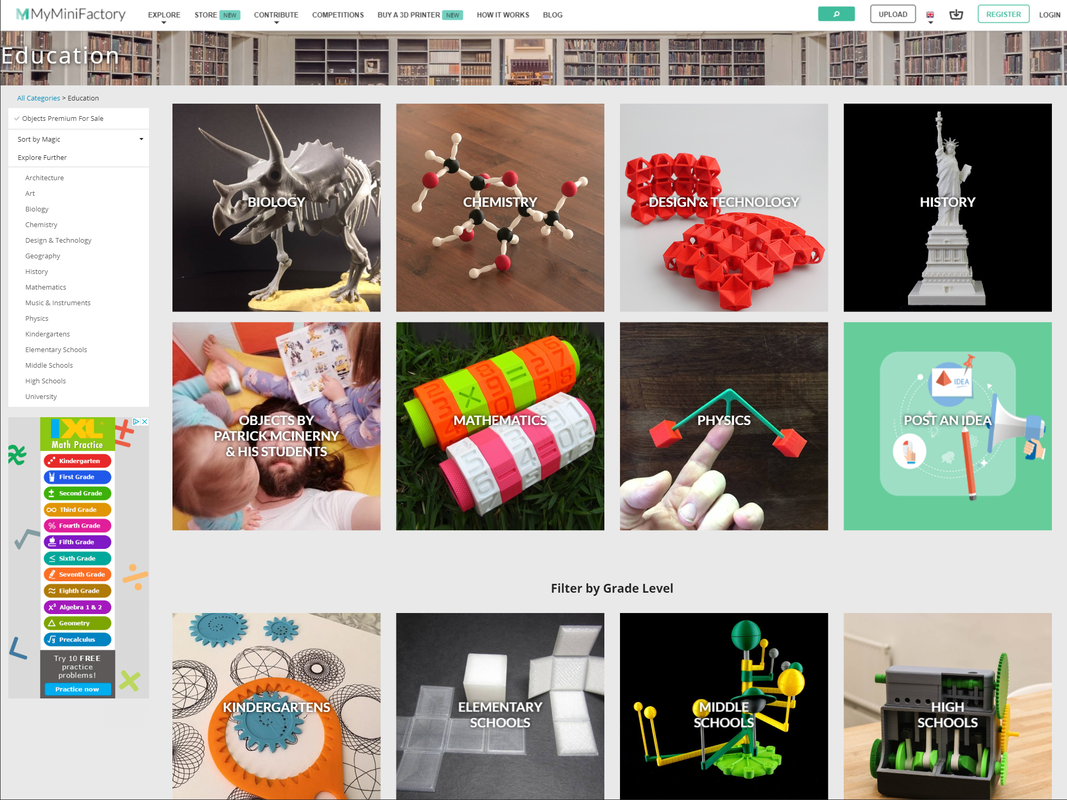

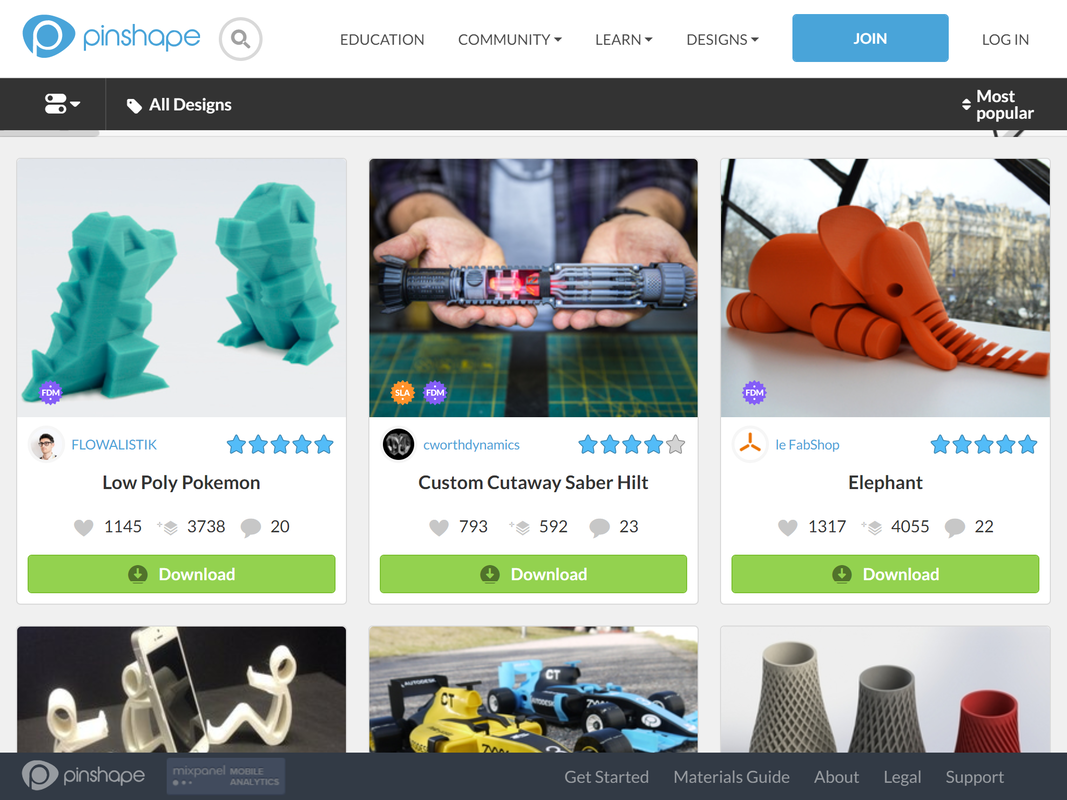

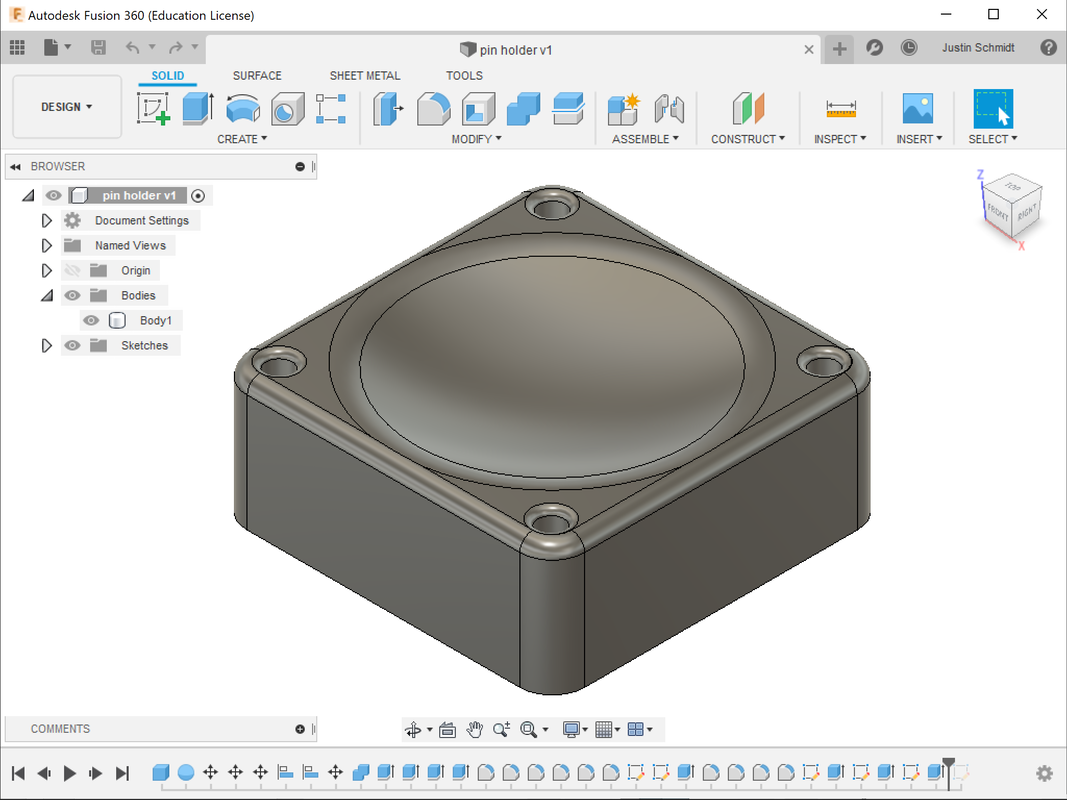

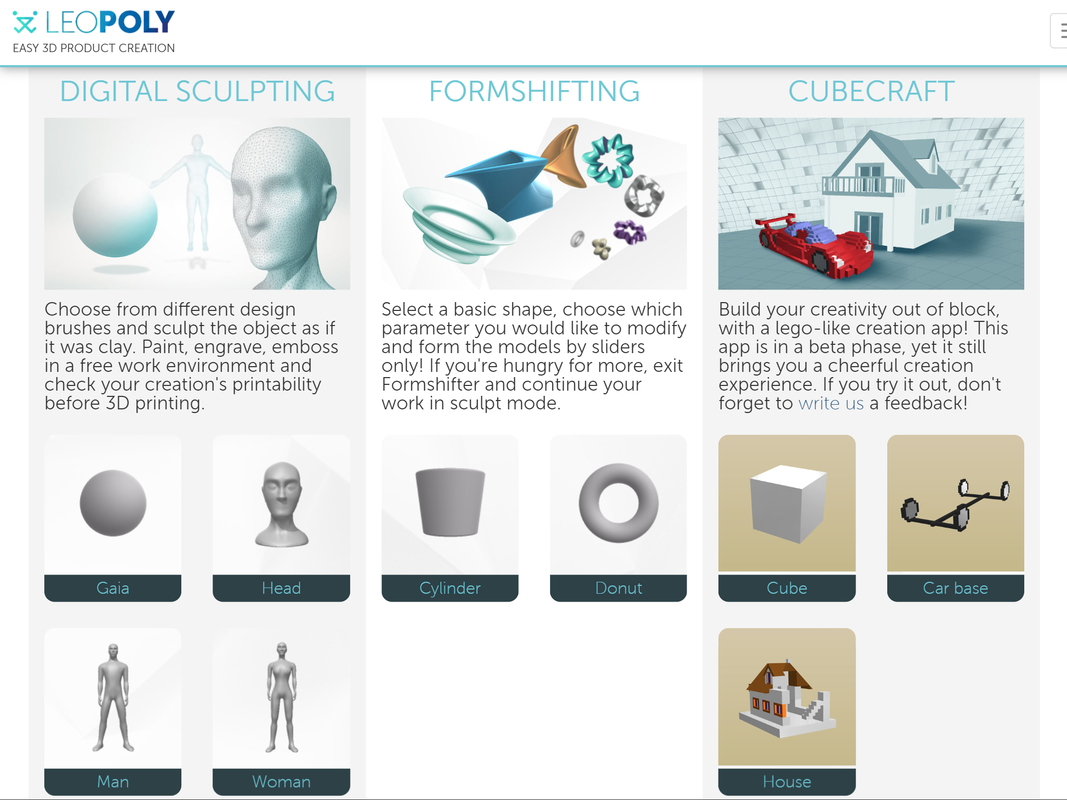

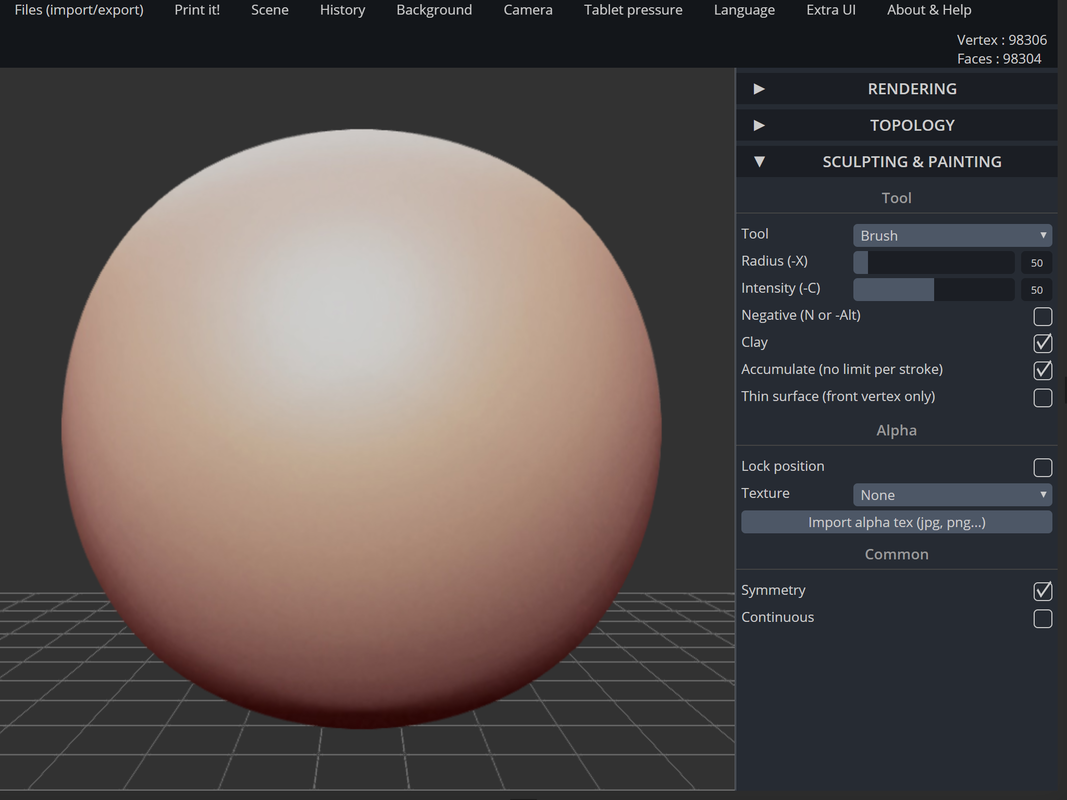

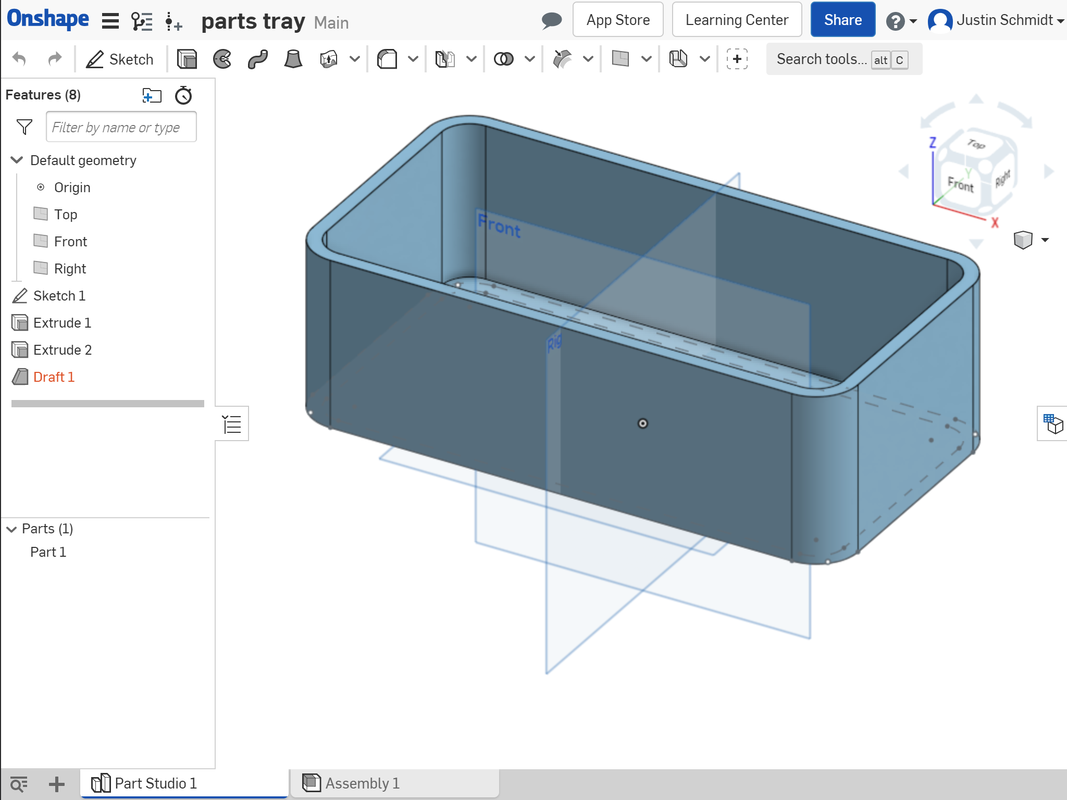

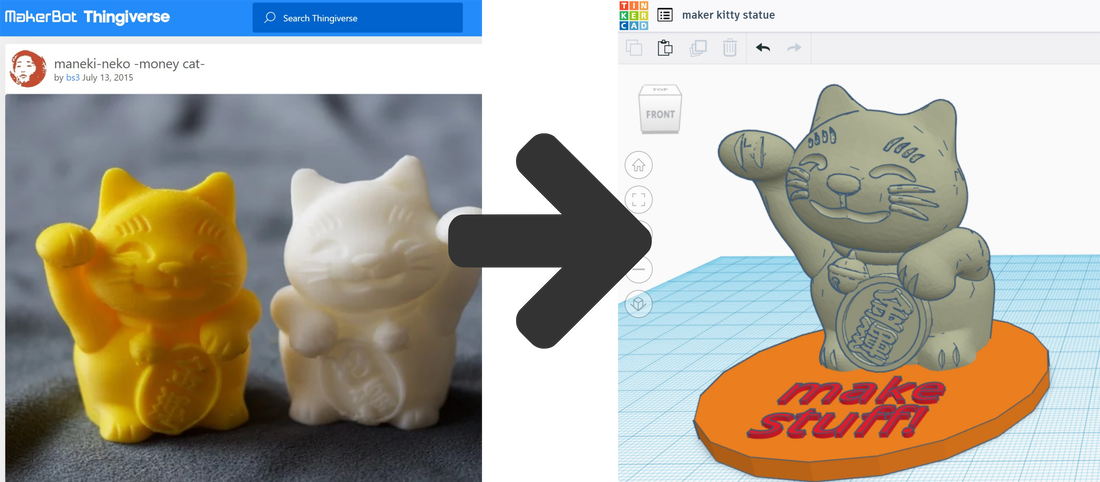

3D Printing and Design

3D printers are iconic makerspace tools for a reason - they are versatile, fairly easy to use, and are fun to watch as they build objects one layer at a time. 3D printing is a method of creating physical three-dimensional objects from a digital model. In order to 3D print, you need three things: